Description

The Induced Draft Blower and Gasket is a crucial component designed for use with gas-fired induced draft hot water boilers. This assembly plays a vital role in the combustion process by creating a negative pressure within the combustion chamber, ensuring the efficient and controlled flow of combustion gases through the system. It helps maintain the proper air-to-fuel ratio for combustion, optimizing energy efficiency and reducing emissions.

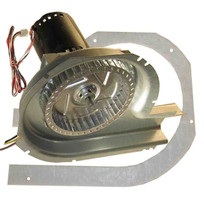

The induced draft blower is a mechanical fan responsible for pulling combustion gases from the combustion chamber and expelling them through the flue or exhaust vent. It creates a negative pressure zone within the combustion chamber, allowing for the continuous flow of gases from the burners. This process enhances combustion efficiency by ensuring that combustion byproducts are effectively removed from the system, preventing backdraft and ensuring the safe operation of the boiler.

The blower is typically driven by an electric motor and is strategically positioned within the boiler system to optimize airflow and combustion. It's constructed to withstand the high temperatures and harsh conditions associated with the combustion process, ensuring long-lasting performance and reliability. The blower's design and size are tailored to the specific boiler model and its heating capacity, ensuring optimal compatibility and functionality.

The gasket included with the induced draft blower assembly serves as a seal between the blower and the combustion chamber. This gasket prevents any leaks of combustion gases, which could lead to inefficient combustion and safety hazards. It's designed to withstand high temperatures and the corrosive effects of combustion gases, providing a durable and reliable barrier that maintains the integrity of the system.